Ceramic WEar Tiles

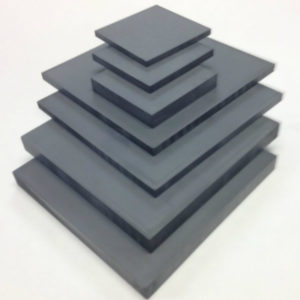

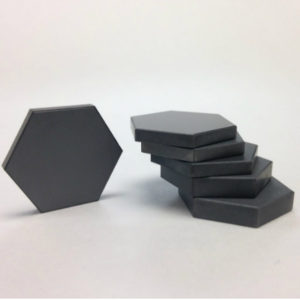

Calix Ceramic Solutions offers a full range of shapes and sized ceramic tiles for your severe wear lining applications. Calix can offer standard-sized tiles (square and rectangular), hex tiles, as well as custom shapes and sizes for your demanding application.

Calix Ceramic Solutions offers a complete material portfolio for these ceramic wear tiles including; several grades of Aluminum Oxide, Zirconia Toughened Alumina, and Reaction Bonded Silicon Carbide.

Calix Ceramic Solutions also specializes in Sintered Silicon Carbide tiles for your most extreme corrosion, abrasive and wear environments.

Please contact us and allow our application engineers the opportunity to work with your engineering

team to recommend the right advanced high temperature tiles for your toughest challenges.

Ceramic Wear Tile Inventory

| Tile Size | Tolerances |

| 4” x 4” x 0.200” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.225” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.250” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.275” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 2” x 4” x 0.290” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.300” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.315” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 4” x 4” x 0.400” Thk | +/- 0.030 L & W, +/- 0.010” Thk |

| 2” x 2” x 0.125” Thk | +/- 0.015 L & W, +/- 0.010” Thk |

| 2” x 2” x 0.187” Thk | +/- 0.015 L & W, +/- 0.010” Thk |

| 2” x 2” x 0.250” Thk | +/- 0.015 L & W, +/- 0.010” Thk |

| 2” x 2” x 0.350” Thk | +/- 0.015 L & W, +/- 0.010” Thk |

| 30mm Hex Tile x 4mm Thk | +/- 0.010 L & W, +/- 0.010” Thk |

| 30mm Hex Tile x 6mm Thk | +/- 0.010 L & W, +/- 0.010” Thk |

| 30mm Hex Tile x 8mm Thk | +/- 0.010 L & W, +/- 0.010” Thk |