Silicon Nitride

Si3N4

Silicon Nitride’s unique properties of high strength, superior fracture toughness, thermal conductivity, and excellent hardness provide a unique engineering material solution for your project’s extreme environments and demanding mechanical / structural requirements. Silicon Nitride 3D Printing benefits from the advancements made in the use of this material in recent years.

Silicon Nitride ceramic Material Characteristics

thermal shock resistance

The low thermal expansion coefficient of silicon nitride material allows for very high thermal shock resistance as compared to other advanced ceramic materials.

fracture toughness & mechanical strength

The interlocking grain structure of silicon nitride material leads to high toughness and mechanical strength at high temperatures.

corrosion resistance

Silicon Nitride composition maintains it’s high strength and hardness at high temperatures allowing the silicon nitride material to resist wear, deformation and corrosion.

Silicon Nitride Properties

| Composition | Grain Size (μm) | Density (g/cc) | Hardness (Vickers) (HV0.3kg/mm^2) | Compressive Strength (MPa) | Flexural Strength (MPa) | Weibull Modulus | Fracture Toughness (MPa-m^1/2) | Poisson's Ratio | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Thermal Conductivity (W/mK) | Coefficient of Thermal Expansion - 20-1000°C (1 x 10^-6 /°C) | Thermal Shock Resistance (ΔT°C) | Electrical Resistivity (Ω-cm) | Dielectric Constant (1MHz) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Si3N4 | 1 - 5 | 3.23 | 1400 | 3500 | 950 | 11 | 8 | 0.23 | 400 | 290 | 28 | 3 | 900 | 10^12 | 8 |

All properties are at room temperature (20°C) unless otherwise stated.

Silicon Nitride products

Silicon Nitride components are a suitable choice for molten aluminum handling due to its non wetting performance in molten metal applications.

welding tips

In automotive vehicle assemblies, control pins and weld locations are used in resistance welding. Silicon nitride has excellent mechanical, thermal, and wear resistant properties, which means it is not affected by the thermal shock and thermal cycling stresses produced during the welding process. These properties provide an improved life expectancy for silicon nitride weld pins.

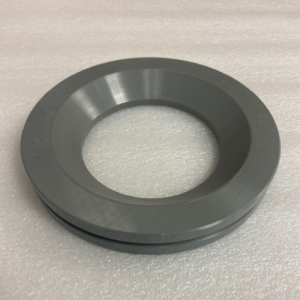

valve seat for ball valves

Valves are used in fossil, nuclear, upstream oil and gas, chemical processing, and mining industries.

silicon nitride faqs

Silicon nitride is a non oxide ceramic material with a chemical compound composed of nitrogen and silicon.

Silicon nitride is made by heating powdered silicon in a nitrogen atmosphere.

Silicon nitride has very low thermal expansion which allows it to have superior thermal shock resistance, high strength, fracture toughness, and hardness, making it an ideal material for severe process applications.

silicon nitride ceramics - pricing structure

- Forming Method – the method used to produce the near net shape component

- Machining Requirements – the type of tooling required and amount of machining necessary to achieve the final product

- Component Details – the specifics of the end user’s components such as tolerance requirements

- Quantity of Pieces