Frequently Asked Questions

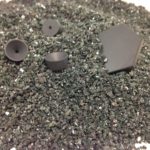

Nitride bonded silicon carbide (NB SiC) is a ceramic material that is formed by reacting silicon powder with nitrogen gas at high temperatures in the presence of a sintering aid, typically magnesium. The reaction between silicon and nitrogen forms silicon nitride (Si3N4) while the sintering aid facilitates the densification of the material, resulting in a dense and high-strength ceramic.

NB SiC has excellent mechanical properties, including high strength, toughness, and wear resistance. It also has good thermal shock resistance and high-temperature stability, making it suitable for use in demanding applications where materials need to withstand harsh environments and high temperatures. NB SiC is also chemically resistant to many acids and alkalis, making it suitable for use in corrosive environments.

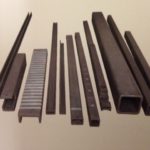

NB SiC is commonly used in applications where high strength, toughness, and thermal stability are required, such as cutting tools, wear parts, bearings, and nozzles. It is also used in aerospace and automotive applications, such as gas turbine components, engine parts, and heat exchangers, due to its excellent high-temperature performance. NB SiC is also used in specialized applications, such as in the semiconductor industry, due to its unique properties.

NB SiC is different from other silicon carbide ceramics, such as hot-pressed silicon carbide (HP SiC) or sintered silicon carbide (SSiC), in terms of its fabrication method. NB SiC is formed by a reactive process where silicon reacts with nitrogen gas, whereas HP SiC and SSic are formed by sintering of silicon carbide powders. NB SiC typically has lower density and slightly lower mechanical properties compared to HP SiC and SSiC, but it can offer advantages in terms of cost-effectiveness and ease of processing.