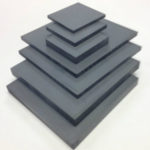

sintered silicon carbide

Frequently Asked Questions

Sintered silicon carbide is resistant to many environmental factors, including corrosion, wear, and abrasion, creep, and thermal shock, and can retain full strength at extremely high temperatures.

Dr. E.G. Acheson created silicon carbide while trying to create artificial diamonds. He then decided to manufacture the material and founded the Carborundum Company in late 1890’s in Niagara Falls.

Sintered silicon carbide can be made in any of the following processes: microwave sintering, reaction sintering, recrystallization sintering, hot press sintering, and pressureless sintering.

A wide array of components can be manufactured with sintered silicon carbide material. The material can be formed in several ways; dry press, isopressing, extrusion and now 3d printing, which allows for the manufacturing of ceramic wear tiles, protection tubes, complex machined near net shapes components, and 3D printed items such as heat exchangers, filters.

Sintered silicon carbide and reaction-bonded silicon carbide are manufactured differently and have different properties. SiC is made without a bonding phase by pressureless sintering fine SiC powder at high temperatures. Reaction bonded SiC is made by infiltrating porous SiC with molten silicon.

SiC is harder and more wear resistant, withstands higher temperatures and corrosion but is more brittle than RBSiC.